Our chemistry, our values

We’ve recently launched a new set of company values for Premier Galvanizing (as part of the wider Joseph Ash Group). They are collectively called ‘Our Chemistry’ – to reflect our excellent relationships with each other, our clients, suppliers and partners, and the chemicals we use in our galvanizing processes.

To create the values, we held several focus groups across the plants to find out what was important to our team members and what values they wanted to live by at Premier Galvanizing and Joseph Ash. We spoke to colleagues on the shop floor, administration and service teams at Head Office, and Commercial Teams at our different divisions. Everyone was offered the opportunity to share their thoughts on what our culture and behaviour look like when we’re at our best and what needs to be added to ensure the Joseph Ash Group thrives and grows.

The resulting values are:

Growth through teaching and learning (internally and externally) is the catalyst for everything we do. We lead with experience and heritage, but we’re also enthusiastic about advancing and improving our products, processes, the industry and ourselves.

We thrive on team spirit, whether we’re looking out for each other’s safety or working together to meet targets. Providing help and assistance, celebrating achievements, and laughing are the elements that bind us together. We have each other’s backs.

We respect each other and our differences and treat people as we want to be treated ourselves. We mix kindness with good manners and listening skills. We also appreciate family: not only in our home lives but also in the family we have at work.

The safety and success of our business and our future sit in our hands. We know what is expected of us as individuals and teams and demonstrate a ‘can-do’ attitude to get things done.

If you’d like to know more – or if you’d like to join our team – please get in touch!

Next page

To help you plan ahead for December and January, please find below the festive period opening hours for our plants:

Premier Galvanizing Corby

Will be closed from 23 December 2022. (Last day for deliveries is 22 December 2022.)

Will re-open on Tuesday 3 January 2023.

Premier Galvanizing Hull

Will be closed from 22 December 2022. (Last day for deliveries is 21 December 2022.)

Will re-open on Tuesday 3 January 2023.

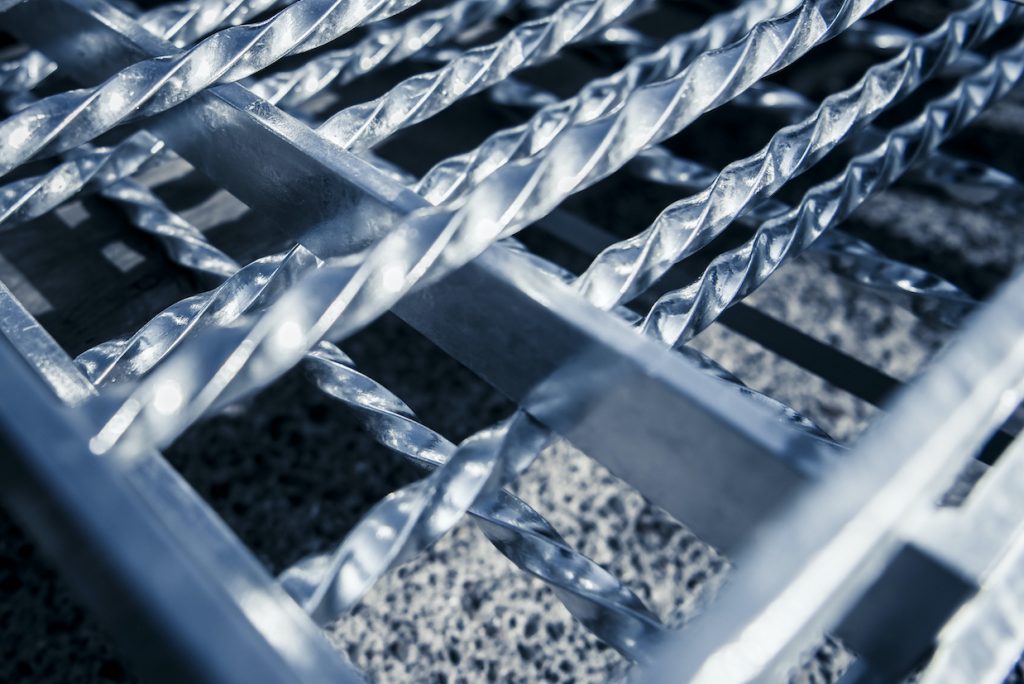

Welcome to our A-Z of Galvanizing – everything you’ve ever wanted to know about galvanizing if you work with steel.

Pre-treating steel to ensure it is free from surface contaminants is a fundamental part of the hot dip galvanizing process, as zinc will not react to unclean metal. As part of the pre-treatment stage, steel is pickled in acid to remove mill scale and rust, producing a chemically clean surface for galvanizing.

Different bath sizes suit varied steel fabrications. No matter how large your steel, we can help. Across all Joseph Ash Group plants, we have a range of bath sizes to suit the smallest to the largest of jobs. Visit our bath dipping sizes page for more information.

A circular economy encourages materials to be made, remade and recycled. Hot dip galvanizing fits perfectly into a circular economy because it optimises the durability of steel (enabling it to be used again) and facilitates the ease of reuse. It can also be recycled if there’s no immediate need to repurpose it. Read The sustainability of galvanized steel for more detailed information.

When designing steel for construction, also design it for galvanization, as a good design will prevent any processing problems at the galvanizing plant and ensure the best steel coating possible. For design advice, talk to our Technical Team. They’d love to help. You can also download Safe Design for Hot Dip Galvanizing.

At Joseph Ash Galvanizing we are committed to preventing pollution and minimising environmental impacts. For every process of our operations, we take a proactive approach to controlling emissions and ensuring the highest protection for the environment. Follow how we do this in Our Green Future – a fun, interactive graphic showing all our service steps, from collecting steelwork from a customer to its delivery at the end destination and all our environmental processes along the way. See it on our website

Once steel has been hot dip galvanized, a small amount of surface finishing may be required to smooth, clean or condition the metal. This is known as fettling.

The Galvanizers Association provides free authoritative advice on hot dip galvanizing since 1949. Visit their website for a wealth of steel and coatings information.

Health and safety at a galvanizing plant are of the utmost importance. At Joseph Ash Galvanizing, we are committed to ensuring our plants are safe environments to work and visit.

ISO standards dictate ways of doing things, whether making a product or providing a service. They are the distilled wisdom of people with expertise in their subject matter. There are many different standards that Joseph Ash Galvanizing complies with to ensure we provide the best service and product for our customers. Examples are the Coatings Requirements of BS EN ISO 1461:2022, the Quality Management System of ISO 9001, and the Environmental Management System of ISO 14001.

A jig holds steel in place in the correct orientation throughout the galvanizing process to facilitate ease of handling.

Galvanizing baths are also known as galvanizing kettles. They are large rectangular structures made from steel plates welded together. They come in many sizes. (We have a range of sizes across Premier Galvanizing and the wider Joseph Ash Group.) Galvanizing kettles are filled with zinc, which becomes a liquid state when heated to 438-460C. Steel that needs to be galvanized is lowered into a kettle at an angle so that the zinc can coat the steel.

Steel is a tough, durable metal; it can last for decades when appropriately treated. In the UK, galvanized steel (with a typical thickness of 85 microns) can last about 85 years before it needs maintenance. The lifespan does depend on the environment, however. For example, the lifespan might be slightly less in damp coastal areas or places with high levels of Sulphur Dioxide. For more information, view the Galvanizers Association corrosion map. It’s an excellent resource for calculating the levels of corrosion in atmospheric conditions across the UK.

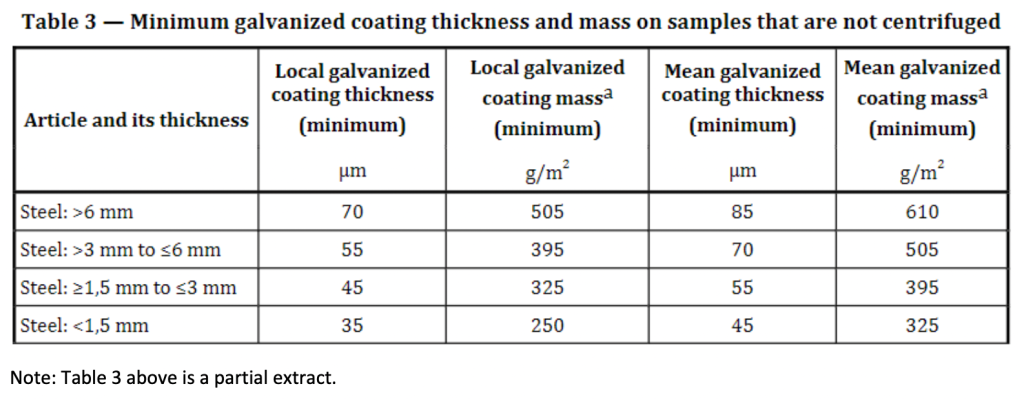

A micron signifies one thousandth of a milimetre. In the steel and galvanizing industry, in order to be standards compliant, >6mm thick steel requires an average coating of 85 microns. This can last for a century in many UL settings.

As stated by the Galvanizer’s Association: “It is astonishing to think that a coating, just thicker than a sheet of A4 paper, can protect a steel structure for the better part of 100 years.”

At Joseph Ash Galvanizing, we mainly galvanize large items such as lampposts and motorway barriers for our clients. What about the small steel parts that hold the bigger pieces together, though? The nuts and bolts? Yes, we galvanize those in a spin bath at our Telford plant. When nuts and bolts are used to hold parts of a bridge in place, it’s just as vital that they are rust resistant too.

Hot dip galvanizing is a chemical process, carried out by highly skilled operatives. At Joseph Ash Galvanizing, many of our valued team have been honing their skills over periods of 20, 30 and 40 years, which means your steel is in safe hands.

Powder coating is a paint mainly applied to metals to provide a harder finish than a normal paint. The paint is applied as a powder electrostatically from a spray gun and is cured in an oven under high heat to form a tough, durable skin. Powder coating paints come in many colours and can be used to create different finishes, such as textured or metallic.

Quenching is the process where steel is rapidly cooled after it has been lifted from the galvanizing bath by immersion in water and/or a dilute chromate or phosphate solution.

Steel is made from iron, which rusts when exposed to water and oxygen. Rust is the result of a chemical reaction called corrosion. To prevent rust from forming, hot dip galvanizing coats steel in zinc. The zinc reacts with oxygen and carbon dioxide to form zinc carbonate. This becomes a protective barrier, stopping water and oxygen from reaching the steel.

Small items such as nails, chains and screws need to be as rust resistant as the steel structures they support. However, they are too small to galvanize in a hot dip galvanizing bath. With spin galvanizing, small items can be placed in a perforated basket and immersed in molten zinc. Once the zinc/alloy layers form, the basket is centrifuged at high speed so that the spinning action removes the excess zinc and creates a clean profile.

Wherever you are, or wherever the end destination for your fabrications is, Joseph Ash can transport them for you using our large fleet of specially equipped lorries, including articulated, rigid, and Hi-ab craned vehicles.

The ability to collect and deliver steel is vital as we like to make life as easy as possible for customers.

Galvanizing baths protect steel against rust, enhancing its lifetime. But galvanizing baths need protection, too, so they can continue to galvanize. Non-destructive testing is used for this purpose. The testing involves ultrasounds which determine the thickness of a bath over time. If the bath becomes too thin, it could crack. Not only would this put the bath out of action for many months, but it would also be perilous for our team if molten zinc leaked onto the floor of the plant.

To achieve the best quality zinc coating, it is important to ensure that the molten zinc can flow freely over all surfaces, externally and internally. So, where there are sealed hollow sections or cavities, vent and drain holes are essential. Please download Venting Tips for Hot Dip Galvanizing.

Our galvanizing plants are self-contained – with steel going in at one end and the final product coming out at the other. This means we can control the amount of waste we produce. At Joseph Ash Galvanizing, we minimise waste by recycling it at almost every stage of our operations. For example, Zinc that oxidises on the surface of our baths is removed as ash and recycled, and waste heat is used to warm pre-treatment tanks. Any wastewater generated can also be treated and reused, with only small volumes of stable solids requiring external disposal. See our Green Plan for further examples.

At Joseph Ash, we want to make our customers’ lives easier. We do this by providing a range of additional services which include: Collection and delivery, Additional paperwork if requested, bundling, packing and labelling of all steelwork, passivation post-galvanizing, on-site storage, full technical support, a one stop-shop service.

At Joseph Ash Galvanizing, the essential part of our process is you – our customers. We hear your requests and treat your steel according to your needs. Whether you need hot dip galvanizing at a certain level of microns, or a duplex coating with a particular colour and finish, we will help. We’ve been in business since 1857 because you have trusted and kept us here.

Zinc is a chemical element with the symbol Zn and atomic number 30. It is found in mineral deposits along with other base metals, such as copper and lead.

The galvanizing process coats steel in zinc, which acts as a protective barrier against water, the leading cause of rust. The zinc in a galvanizing bath is molten at 450°C. Once the steel has reached this temperature, it is ready to be lifted from the bath.

How the updated standard affects the galvanizing industry and customers

ISO 1461 – the British Standard for hot dip galvanized coatings on iron and steel articles – has recently been updated. The new 2022 version supersedes the 2009 version.

The standard will be adopted by CEN (the European Standards Organization) and subsequently by National Standards Bodies, including BSI in the UK and the National Standards Authority of Ireland.

Several important changes have been made to the document. As the changes affect both us – as galvanizers – and you – our customers – we’ve listed them below:

Summary of major changes

The most significant changes to the document concern the galvanizing of ultra-low reactive steels, coating thickness measurements on ancillary elements, removal of flux residues and zinc ash, and the renovation of galvanized steelwork.

There has been no fundamental change to the method of assessment of coating thickness, but allowances for measurements on ancillary elements and ultra-low reactive steels have been introduced. The revised standard states that thickness measurements should not be taken on ancillary elements (e.g. brackets) unless specifically requested by the customer. Recognition that certain steel compositions can exhibit ultra-low reactivity during galvanizing (i.e., cannot satisfy the standard minimum coating thickness requirements) has been introduced. Articles produced from steel with a section thickness greater than 3mm which have a composition of ≤0.01 % silicon AND an aluminium content >0.035 %, that exhibit ultra-low reactivity during galvanizing, can now be subject to lower coating thickness requirements (see 6.5 below). The variation to the standard requirements must be included in the Declaration of Compliance if one is to be provided.

An important change has been made with regards to removal of flux residues. In the 2009 version, flux staining/residues were not permitted anywhere on the article, but the updated version now acknowledges that removal (including zinc ash) in some fabrications is practically impossible. Therefore, if ‘access is restricted, for example inside hollow sections’ flux residues and zinc ash are permissible.

The key changes to the content on renovation of galvanized steelwork are the requirement for the pigment in a zinc-rich paint to conform to ISO 3549 ‘Zinc dust pigments for paints — Specifications and test methods’ which has been removed but must still offer sacrificial protection to the steel; and also, more comprehensive information within Annex C – Renovation of uncoated or damaged areas.

Changes in ISO 1461:2022 vs 2009 edition

1 Scope – No significant changes were made to the scope, however clarification to clearly state the standard specifies the general properties of, and test methods for, ‘hot dip galvanized’ coatings were incorporated.

2 Normative references – There has been slight changes to the standards contained within the normative references to reflect their status within the document. Notably, ISO 14713-2 ‘Zinc coatings — Guidelines and recommendations for the protection against corrosion of iron and steel in structures — Part 2: Hot dip galvanizing’ has been included.

3 Terms and definitions – Five new terms, galvanizer (3.3), after-treatment (3.18), additional coating (3.19), wet storage stain (3.20), duplex system (3.21) have been introduced to allow for simplification of the main text.

4 General Requirements – No significant changes.

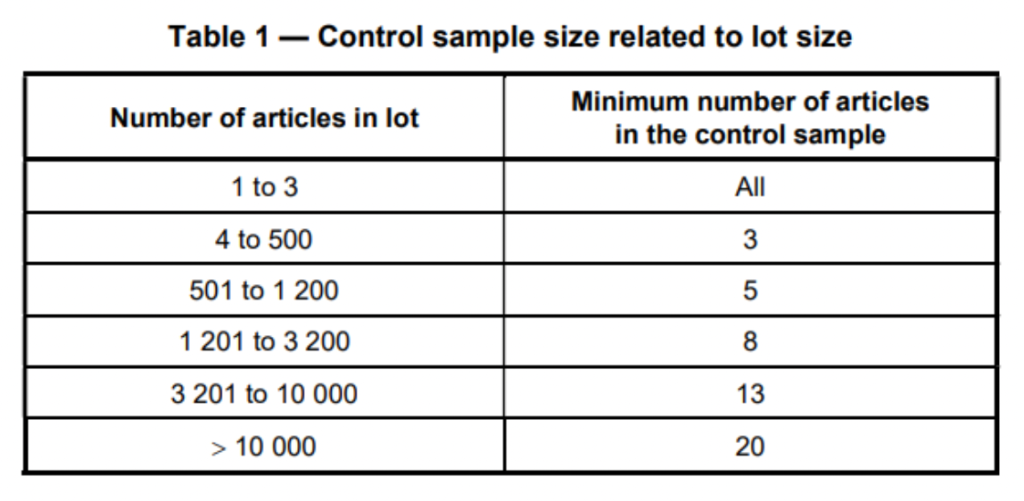

5 Acceptance inspection and sampling – No significant changes, except the minimum number of articles in a control sample can be subject to deviation following agreement within the supply chain. The new text now reads ‘Unless otherwise agreed, the minimum number of articles from each inspection lot that forms the control sample shall be in accordance with Table 1.’

6.1 Galvanized coating properties – Appearance – Clarification has been made that only the visible significant surfaces are subject to the appearance acceptance inspection. Flux residues and zinc ash shall be removed where they can affect the intended use of the HDG article, or its corrosion resistance requirement, unless access is restricted, for example inside hollow sections. Previously, flux residues were not permitted anywhere on the article.

The coating, when first examined by normal vision from a distance of not less than 1m shall be free from blisters (i.e. raised areas without solid metal beneath), roughness and sharp points (if either that roughness or sharp point can cause injury) and uncoated areas. The 2009 version also included ‘Nodules’, however this has now been omitted from the list of prohibited coating features.

6.2 Galvanized coating properties – Thickness – The greater relevance of ISO 2178 ‘Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method’ amongst the other coating thickness measurement standards has now been acknowledged.

6.2.3 – Reference areas – now states that ‘Unless otherwise agreed, reference areas shall not be chosen from ancilliary elements, when they are significantly smaller than the main elements of a larger article’ due to being thinner or less reactive. Acceptance that flame-cutting, laser-cutting and plasma-cutting can lead to the steel being more unreactive during galvanizing and decreased cohesion of the coating has been made. The 2022 edition now reads ‘In order to obtain the required coating thicknesses more reliably and to ensure adequate cohesion or adhesion of the coating, flame-cut, laser-cut and plasma-cut surfaces should have been ground off and sharp edges should have been removed during fabrication and prior to delivery to the galvanizer.’

The minimum size of a reference area is now clearly defined as being 10cm2.

6.3 – Galvanized coating properties – Renovation – The circumstances where a lower (than 100μm) minimum repair coating thickness can be agreed, has been expanded to account for thinner galvanized coatings around the damaged area, for example, where aesthetics may be important.

6.4 – Galvanized coating properties – Adhesion – No significant changes, however a new ‘note’ has been added which recognises that cohesion of the galvanized coating can be affected by a steel being ultra-low reactive – as defined in ISO 14713-2 Table 1, Note 4. There is still not a suitable international standard for testing the adhesion of galvanized coatings.

6.5 – Galvanized coating properties – Acceptance Criteria – It is within this section where the adjustment for ultra-low reactive steels has been introduced. The new text reads:

‘For articles with steel section thicknesses greater than 3 mm, produced from steels with compositions ≤0,01% silicon that also have aluminium contents >0,035%, that exhibit ultra-low reactivity during galvanizing and therefore cannot satisfy the minimum galvanized coating thickness in Table 3, the next lowest category of steel article section thickness given in Column 1 of Table 3 shall be applied. In such cases, if a declaration of compliance must be provided then it shall state this variation including the adjusted minimum mean galvanized coating thickness requirement that has been applied to the inspection lot.

NOTE – Certain steels, including but not limited to, either steels suitable for laser cutting with chemical compositions as given in ISO 14713-2:2019, Table 1, Note 4 or steels with high surface smoothness, or both, can exhibit ultra-low reactivity during galvanizing (see ISO 14713-2) and the coating thickness achieved on such steel articles can possibly not be dependent on steel section thickness. These factors are beyond the control of the galvanizer and can also result in even lower coating thicknesses than given in the next lowest category of steel article section thickness given in Table 3.’

7 – Declaration of Compliance – The terminology has been modified, in ISO 1461:2009 this was referred to as a ‘Certificate of compliance’ whereas now it is called a ‘Declaration of compliance’. Clarification that this must meet the requirements of ISO 10474 ‘Steel and steel products — Inspection documents’ has been incorporated.

Annex A (normative) – Information to be supplied – An important sentence has been added to A.2– Additional information for provision by the purchaser, which states that ‘an indication of any ancillary elements within the article that must be considered as part of the significant surfaces from which reference areas might be taken (e.g. if the ancillary elements are safety critical).’ This is to account for the default procedure of not taking coating thickness measurements on ancillary components.

Annex B (normative) – Safety and process requirements – Venting and Drainage of Articles – Verification has been incorporated into this Annex that states the work presented for galvanizing should be in accordance with ‘either the guidance given in ISO 14713-2 or any further specific guidance for the articles to be processed that may arise from consultations with the galvanizer, or both.’

Annex C (informative) – Renovation of uncoated or damaged areas – Annex C contains considerably more guidance on the requirements for a zinc-containing paint used for repair than the previous version (Annex C.1 – Zinc-containing paints). See new guidance below.

‘A dry paint film that is capable of conducting electricity and which is in electrical contact with the basis metal will ensure that sacrificial protection is provided.

Other things being equal, sacrificial protection increases with increases in metallic zinc content in the dried film but does not increase further above approximately 94% by weight of zinc for paints containing zinc dust. However, other factors can be important.

A zinc-containing paint with a zinc dust content that is equal to or greater than 80% by mass in the dry film can be considered suitable for renovation of uncoated or damaged areas. Conformity of the zinc dust pigment, within a zinc-containing paint, with ISO 3549 is a further indication of suitability.

Zinc-containing paints based on lamellar shaped, rather than spherical, zinc particles may achieve adequate protection at lower contents of zinc in the dry film than for zinc dust paints with spherical particles.

Zinc-containing paints may also include an aluminium content for aesthetic purposes.’

Annex D (informative) – Determination of thickness – No significant changes.

Annex E (informative) – Corrosion resistance of galvanized coatings – Annex E has been updated to include supplementary information regarding the long-term, steady-state zinc corrosion rates given in ISO 9224 ‘Corrosion of metals and alloys — Corrosivity of atmospheres — Guiding values for the corrosivity categories.’ This is in appreciation that ISO 14713-1 ‘Zinc coatings — Guidelines and recommendations for the protection against corrosion of iron and steel in structures — Part 1: General principles of design and corrosion resistance’ provides first year exposure corrosion rate data and is therefore conservative guidance.

Further information and support

If you have any queries regarding the updated standard, please contact the Premier Galvanizing Technical Team

You can also contact the Galvanizers Association Technical Department regarding the updated standard or its interpretation. Call their free Service Line on telephone: 0121 355 8838 or email Dr Desmond Makepeace at d.makepeace@hdg.org.uk.

Next page

We are delighted to announce that Joseph Ash Limited (the parent company of Premier Galvanizing) has acquired Widnes Galvanising Ltd.

Founded over 20 years ago, Widnes Galvanising has been an independent hot dip galvanizer in the northwest. It is the perfect match for Joseph Ash Limited. Not only do we share similar values – including a mission to provide the very best customer service – but we’re now able to broaden our geographic coverage into Cheshire to service customers in Lancashire, Cheshire, Merseyside and beyond.

The acquisition is also good news for Widnes Galvanising customers, who will benefit from the additional services Joseph Ash Limited provides. For example, extra transport and storage, spin galvanizing, and powder coating.

Our new colleagues from Widnes will also benefit as they will be able to capitalise on the opportunities that being part of a larger group brings, such as career progression, training, and learning new skills.

Stuart Whitehouse, Managing Director of Joseph Ash Limited, said: “Widnes Galvanising is a welcome addition to our Joseph Ash family, and we are thrilled to have them onboard. The acquisition has been smooth, ensuring a seamless transition for the future. While initially trading as a subsidiary company, Widnes will share and exchange technology and expertise with our eight other plants.”

Whitehouse continues, “The acquisition is a wonderful opportunity for all parties involved: the existing Joseph Ash team, our new colleagues from Widnes, our suppliers and customers.”

Further announcements about the acquisition will be made in due course.

For more information, please contact our Head Office on 0121 504 2573.

Next page

Following World Environment Day at the weekend, the Joseph Ash Group has designated the first week of June to be ‘ESG Week’. During this week, we’re raising awareness of the environment and social and governance issues affecting our colleagues, clients, and suppliers.

This is the first year for our new annual event, and so far this week, we’ve delivered presentations on ‘What is ESG?’. We’ve also provided resources (posters and links to activities) to team members to help them understand some of the terminology used (e.g. ‘Carbon Neutral’, ‘Net Zero’, ‘Carbon Offsetting’). Plus, we’ve shared advice on being more energy, waste and water conscious both at work and at home.

Later this week, we’ll be conducting safety tours to reinforce the importance of health and safety in the workplace.

Here are some of the important topics we’re covering:

Environment

- Compliance with all environmental legislation

- Minimise all negative environmental impacts from our operations – emissions to air, water and land

- Minimise our resource usage and support a circular economy

- Reduce our carbon emissions and work towards achieving Net Zero carbon emissions.

Social

- Managing the risks to the health, safety & wellbeing of our colleagues and other stakeholders

- Improve the talent and diversity of our colleagues and create a value-based culture within the business

- Positively engage with our local community by providing support to local initiatives and charities

- Supporting apprenticeships.

Governance

- Effectively identifying, mitigating, and controlling business risk

- Operating in compliance with all applicable legislation

- Ethically conducting business and working with integrity

- Using reputable suppliers and working with customers that support our values

- Ensuring all decision-making is carried out with our values, strategy and impacts considered.

If you want to know more about ESG across the Joseph Ash Group (Premier Galvanizing and Joseph Ash Galvanizing), please get in touch. We’d love to tell you all about it!

Next page

Intergalva takes place in Rome next month, and team members from Premier Galvanizing and Joseph Ash Galvanizing will be attending.

Intergalva is known as ‘the worldwide galvanizing industry’s meeting place’ and we’re looking forward to seeing some of our colleagues from global galvanizing plants, meeting some of our clients and who may attend, and learning about latest industry developments.

A key theme for this year’s Intergalva is energy supply and the future decarbonisation of galvanizing operations.

The event is hosted by the EGGA (European General Galvanizers Association).

Registration is still open if you’d like to attend.

Next page

When using steel in construction, hot dip galvanizing is an essential part of the project to protect the longevity of the metal. You carefully design your steel to fit the overall build of the construction project. But sufficient care and attention are also required when you design your steel for galvanization. A good design will prevent any processing problems at the galvanizing plant and will also ensure you get the best steel coating possible.

Here’s some key design pointers to enable your steelwork to be processed safely whilst giving you the best quality coating.

When sending steel to a galvanizing plant, you will have several goals in mind:

- Fast turnaround

- Premium quality coating

- Excellent service

- Good value for money.

Ensuring steelwork is suitably designed for hot dip galvanizing helps achieve these goals and ensures the steel is safe to be galvanized. Poor design can result in poor coating quality, additional costs, low production rates, and failure to meet delivery dates. Poor design can also pose serious health and safety risks for the people carrying out the galvanizing.

What does good design look like?

The importance of venting and drainage

When steel is immersed in the galvanizing bath, add vent and drain holes to sealed hollow sections or cavities to ensure superheated air can escape all internal spaces and the molten zinc can flow freely over all surfaces, external and internal. Failure to adequately vent would result in trapped air causing an explosion and endangering galvanizing workers. It would also cause zinc build-up where the excess zinc cannot drain properly.

The sizing and location of vent holes are just as important as the provision of these holes. As a guide, make the venting holes as large as the steelwork can manage (but talk to your galvanizer for the best advice for your fabrications). The hole locations will be determined by how the steelwork is hung on the jigs at the galvanizing plant.

When adequately sized and correctly located, vent and drainage holes will:

- Significantly reduce the risk of injury to galvanizers.

- Allow faster immersion and withdrawal speeds which will help to minimise excessive coating build-up and reduce the risk of distortion by minimising temperature differentials.

- Virtually eliminate the risk of damage to product, plant and equipment caused by the explosive vaporisation of entrapped moisture or air.

- Improve the characteristics of the galvanized coating by restricting the effects of zinc solidification during drainage and reducing the mass of zinc required to achieve a good finish.

Size, weight, and shape matter

To ensure a good hot dip galvanizing finish, size, weight, and shape really do matter. A fabrication design should ideally incorporate easily handled components or fabrications which can be single dipped or subsequently assembled by bolting with galvanized fastenings. Double dipping is a possible alternative. Seek advice from your galvanizer before proceeding.

Suspension holes or lifting lugs may be needed if there are no suitable points for locating hooks or wires. Once again, lifting points should be positioned to maximise venting and drainage.

Minimising distortion

You will not want your steelwork to become distorted during the galvanizing process. To minimise distortion, fabrications should ideally be symmetrical, suitable for single dipping, and incorporate sections of as near equal thickness as possible at the joints. Components should also fit perfectly to avoid force or restraint during joining. Use continuously welded joints with balanced welding techniques to reduce uneven thermal stresses and the largest possible radii on all curved members.

Design is just part of the story. It’s also essential to choose your galvanizer wisely

As well as following the rules of good design for pre-galvanized steel, take care when choosing your galvanizer.

Health and safety standards

Look for a plant with exemplary health and safety standards. One where the plant managers work hard to keep all colleagues and visitors safe with up-to-date equipment, sufficient PPE, good air quality, and clear-to-follow rigorous shop floor processes. And one where team members work safely on every job by thoroughly inspecting steel from the point it is delivered and at key intervals of the galvanizing process to ensure projects will not pose health and safety risks.

Training

Look for a galvanizer that not only trains team members on all aspects of safety in galvanizing, but also teaches clients and the wider industry. At Premier Galvanizing for example, we issue ‘Safe Design for Hot Dip Galvanizing’ posters to our clients as reference guides for steel preparation. We’ve also published a ‘Design for Galvanizing’ video (available on our website and YouTube), and we run ‘Design for Galvanizing’ seminars onsite for client teams.

Technical help

A final piece of advice is to always look for a galvanizing company happy to be on hand to provide technical advice on all aspects of pre-galvanized steel preparation.

Premier Galvanizing has a Technical Support Team who will answer any steel fabrication questions from clients. The team members are also happy to visit fabrication shops and advise on venting requirements to ensure fabrication issues can be resolved before the steel reaches the galvanizing plant.

We hope you’ve found these pointers helpful. For more information, please get in touch with a member of our team. There is also lots of helpful information freely provided by the Galvanizers Association.

Next page

As sustainability and good emission management are critical drivers for Premier Galvanizing, we always try to look for suppliers with like-minded responsible approaches to the environment.

Kall Kwik Birmingham is one of our suppliers, and we were proud to welcome them into our vendor family three years ago, as their green initiatives are admirable.

In 2019 Kall Kwik Birmingham joined Carbon Capture®, a unique market-leading, high impact, low-cost environmental initiative that creates new native woodland in the UK.

Through their involvement with Carbon Capture®, Kall Kwik enables all customers who order paper/print from them to capture the CO2 emissions from their purchases by planting native woodland through the Woodland Trust and the Woodland Carbon Scheme.

_______________________

What is Carbon Capture®?

- A method of mitigating CO2 emissions and providing a reduced carbon solution for organisations

- Creates native woodland in the UK and provides habitats for wildlife and green spaces for all to enjoy

- A demonstration of an organisation’s values and responsible approach to the environment.

Woodland Carbon and The Woodland Trust

- Woodland is the second-largest sink of CO2 after the oceans

- The CO2 is captured by the planting of trees in new native woodland here in the UK through the Woodland Trust’s Government-backed Woodland Carbon Scheme

- The scheme operates under the HM Government’s 2011 Woodland Carbon Code www.woodlandcarbon.co.uk

- 100% of the Carbon Capture charge goes directly to the Woodland Trust to plant native woodland in the UK

- The Woodland Trust is the leading UK woodland conservation charity (Charity no. 294344 /SCO38885)

- Woodland Trust aims to protect and develop natural woodland throughout the UK, thereby protecting our natural heritage

- The Trust owns and manages over 1,000 free-to-visit woodland sites across the UK. The UK has just 13% woodland cover compared to the European average of 37%.

____________________

Since joining Carbon Capture in 2019, Kall Kwik Birmingham has captured over 8500 tonnes of CO2, equating to about 210 sqm of new native woodland – roughly 35 trees!

Dene Sproson from Kall Kwik said:

“This is a fantastic achievement. Kall Kwik Birmingham and our clients should not underestimate this contribution. Whether it be 30 trees, three trees, or 3,000 trees we have helped to plant, our combined contribution to the overall programme is massive!

The critical thing we feel is that Kall Kwik Birmingham and our clients have committed to Carbon Capture®, helping to plant trees and further promote the initiative, which overall contributes to the government’s targets and commitments to NET-ZERO!”

Welcome to the Premier Galvanizing family Kall Kwik Birmingham. We look forward to a long relationship with you – and to planting more trees!

(Photo by Casey Horner on Unsplash)

Next page

The Easter bank holidays will soon be upon us, which means our plants will be closed for the long weekend, giving our team members a well-deserved break.

If you have projects that need completing around this time, book the work in early so that we can complete it for you.

All Premier Galvanizing and Joseph Ash Galvanizing plants will be closed from Friday 15 April to Monday 18 April 2022.

We hope you have a great bank holiday weekend too!

Next page